When I first held the M200HT in my hands, I immediately knew that I would need to own this knife. I initially understood, why Pinesurvey was so totally full of praise for it. The M200HT is a beast of a knife which is usually something that’s right up my alley. Still it’s an absolute “no nonsense” tool.

Acta Non Verba markets the knife as part of its “M” as in “Military” collection. These are top tier fixed knives with a focus on usage and a very high level of craftsmanship. This very blade was designed in cooperation with “Hard Task” a tactical training facility in the Czech Republic. Thus the name.

First impression of the M200HT

Full disclosure: I got this knife from ANV in exchange for an honest review. If you know me just a bit then you know that I’m taking a task like that very seriously. Now that ANV is part of the Perunika portfolio I thought it’s way due to to write this review.

Unpacking

When you first take out the knife of it’s very stylish black box you immediately have the same effect as with every other ANV knife I had so far. These things are extremely smooth and nice to the touch. There are just no sharp edges – safe for the edge of the blade. Everything is round and smooth. Still it’s never slippery. At first glance you can tell that the Kydex sheath is well made and has a lot of different options to mount it. When you first draw the knife you can tell that the retention is perfect. You won’t lose the knife, not even when carried upside down but it can still be easily drawn.

The very blade has a nice dark DLC coating. It’s not exactly black but a very nice grayish brown that fits the handle. Speaking of the handle – it’s an ergonomical masterpiece. It fits into your hand like an extension. It’s heavily structured but not so aggressively that your hand might hurt if you work without gloves.

Unlike other knives that usually have a very distinct smell of oil or grease, the blade of the M200HT reminded me of a fresh cologne. I’m sure it’s also some residue from the production process but I just thought it’s funny enough to mention.

First test runs

Of course I couldn’t resist and started testing right away. On the first day I put the M200HT with it’s sheath on my belt and took it for a long walk with our “best friend operator” Ronja. First I used it to hack free a way were some fast growing plants started to close one of the paths in the small wood where we regularly walk. As expected, the blade was sharp enough to cut even very light shrubbery without holding the plant fast. Thicker branches were no problem of course – I just usually don’t hack through them because I don’t want to disturb nature too much.

Then I collected some hard wood and made a few tests. Hacking off twigs, hacking a point on one end. Then carving a point on the other end. And making some feather sticks out of twigs. Hacking and chopping wasn’t a problem of course. But even some fine carvings after that didn’t pose any problem at all. So far everything was as expected. The knife excelled at basic tests but yet I tried nothing that could bring a high class knife to it’s limits. I wanted to change that the next day.

Fun fact: That “light testing” still gave my fitness tracker the impression that I was in an accident so that it sent a distress call to my wife.

Harder tests

Usually when I test knives I start slowly and then work up more and more. This way I get used to the knife and get a feeling for it’s capabilities. I like to bring a good tool to it’s limits but I hate to destroy something on purpose. Well, what I saw and heard of the M200HT gave me a lot of confidence so I just thought I could jump directly to the top and do some hard tests.

So I searched the banks of a close river for a wrecked bicycle. Unfortunately you usually don’t have to search for long, it’s almost given that you’ll find one. When I found one, I startet cutting and hacking at everything on the bike that was still distinguishable. The order is important since some things cause more wear than others.

- I cut through the wire-armored tires

- I hacked into the metal frame of the bike

- I hacked several times into the wheel leaving deep marks

- I cut the tube into ranger bands

- I tried to cut some of the spokes but gave up because they were too floppy and I didn’t want to use stones as a cutting board. So I just hacked into them a few times

Initial Test results

After that, the blade was not impressed at all! All the more I was impressed. Following the laws of physics and metallurgy the blade was not sharp enough to shave off very fine hair. But it was still sharp enough to cut very thin shavings off of very hard wood. If you know wood that was carried by a river for some time and then left in the sun to bleach – this is extremely tough. Still, no problem to make shavings and feather sticks.

When I took a closer look and used a stropping belt to resharpen the blade I found that I had hammered a microscopic burr into the edge. That was all. No nicks, no break outs, nothing. Not even a scratch in the coating. A few strokes with the finest diamond of the Worksharp Pro and now the blade is back to razor sharpness.

If you’re not into knives that much – this performance is extremely impressive. Usually I would expect to have nicks in the blade that are big enough to see or at least feel. Or evenly likely, to have small pieces break out of the edge. And scratches in the coating. To be honest, what I did was utter abuse but it didn’t leave a mark.

The build of the ANV M200HT

Like you would expect from a knife like the M200HT the point of balance is in the finger choil right behind the hilt. Combined with the long handle this gives you a lot of different options. Grip it close to the hilt and you have a very swift blade that doesn’t weigh heavy in your hand. It might sound strange for a knife that size but when held like this you can use it for very fine work.

Just slide your hand back along the handle and you have a versatile chopping tool. You’ll grip behind the point of balance and the same knife will feel like a machete or an axe.

The blade

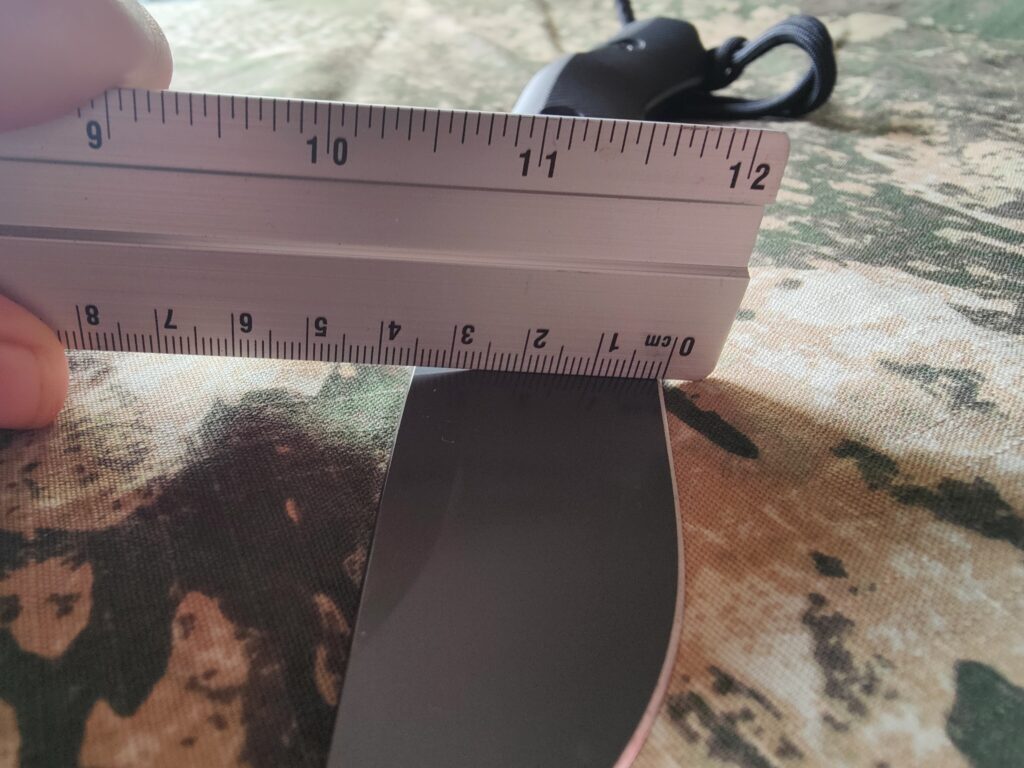

The blade is a very subtle drop point shape with an even subtler recurve. It’s very “not fancy” but uses a proven and tested shape that has been in use and improved almost as long as knives are in use. It’s a rather high flat grind which makes for good cutting capabilities. On the other hand it makes the blade lighter but also takes away stability. From what I’ve seen so far the choice of steel and heat treatment is so good ANV just relies on it without sacrificing “sliciness” for stability. A well thought through choice as far as I can tell for now. The perfect balance between toughness and cutting capabilites. With 5mm thickness the blade has enough “flesh” to withstand hard abuse.

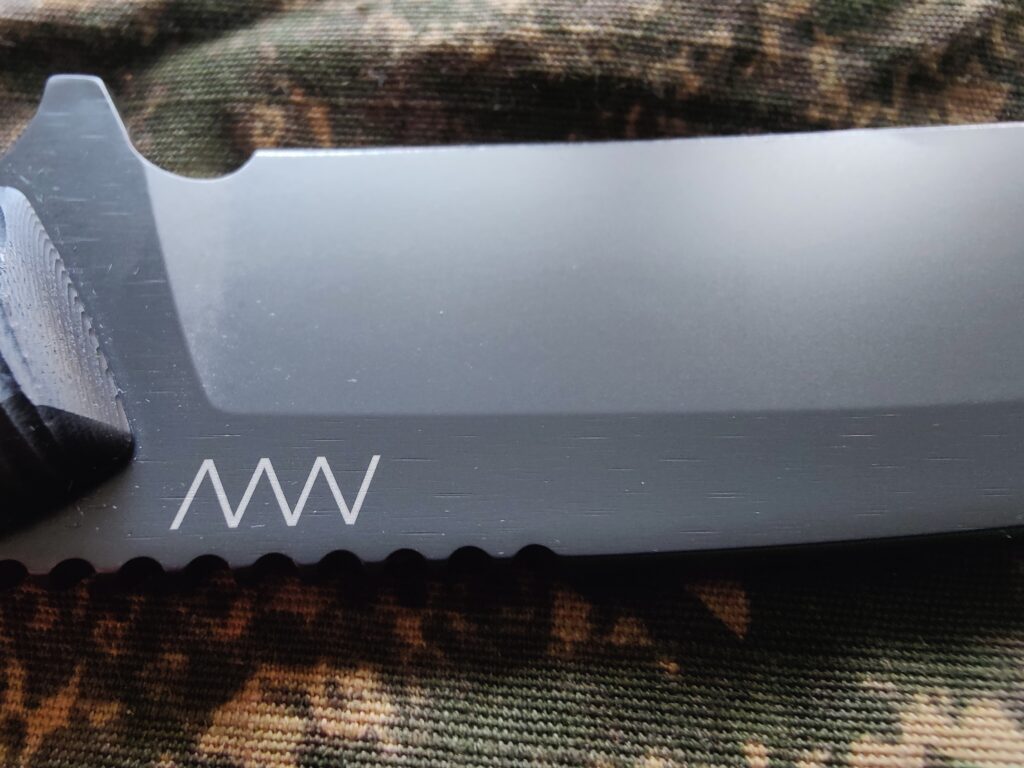

Dark DLC coating covers the whole blade. The part between the grind and the spine shows a few traces of milling which gives the whole blade a very interesting duo tone look. If you’re worried: you can see the traces only with magnification or provoked reflections. So that’s definitely not a flaw.

Like all ANV blades the M200HT also has their “wave” logo on the left side. The other reads: “M200Hard Task | Sleipner * | Made in Czech Republic”. The asterisk indicates the cryogenic hardening process which goes to 59HRC. That’s a bit lower than ANVs EDC blades which is an excellent choice. It’s well hard enough to have great edge retention but it’s way easier to resharpen in the field. And of course it’s way less likely to break.

Special features of the blade

Close to the handle there’s a small choil that’s not coated. It’s marked with “fire steel” and has sharp edges so you don’t have to use the main edge to start a fire. The position is well thought through because most knives have a small choil there anyway to allow for easier sharpening. Why not use it for a fire steel as well.

Some jimpings on the spine help with resting your thumb on the back of the blade to add more control when cutting. They help to make the knife less slippery but still won’t hurt after prolonged work.

The handle

The handle is longer than that of most knives that size. It also has a distinct curve and a choil. The M200HT is a full tang knife where the G10 scales are screwed to its sides. You can feel the tang around the handle which works well due to its rounded edges. As I said before the grooves in the scales help with a very good grip even when cold or wet. In fact the whole handle has a very complex 3d shape. I let people with differently sized hands hold the knife and everyone was pleased with the grip. It seems like Acta Non Verba managed to achieve something close to impossible: They built an ergonomically shaped handle that still fits most sizes.

The angle helps with holding it firmly even with different grips. When you use the “hammer” grip close to the hilt, you have your index finger in the choil. It gives excellent control when doing precision work. Or when you need a lot of power when carving. But you can also slide your hand to the end of the handle, behind the point of balance. This gives great chopping characteristics. The knife comes with a paracord lanyard at the end of the handle that will keep it from slipping when chopping.

The lanyard hole is placed in a small part of the tang where there are no scales. This part can be used as glass breaker. Or coconuts or whatever needs breaking.

Another thing that’s hard to comprehend how ANV managed to build is the flexibility of the handle. Usually, either you have a very ergonomically shaped or you have one that’s fit for different grips. The M200HT still allows to hold the blade in different directions and still have a firm grip.

The sheath of the M200HT

The knife comes with a very well made Kydex sheath that holds it securely, even upside down. Yet, it’s not hard to draw. As usual by ANVs sheaths there’s the “wave” logo engraved and you have a lot of mounting options. It comes with pre-mounted PALS clips that also work with belts of different sizes. But the edges of the sheath have many holes to screw on whatever you want to use to mount the sheath. There are even slits to run webbing through. A quite big drainage hole reaches from the edge of the sheath to the tip of the blade.

Further tests

Since I’m not satisfied with a few initial tests, I went on to come up with things I could throw at the M200HT.

Slippery handle

With such a sophisticated shape on the handle it’s just natural to test how it performs when it’s slippery. Oil, mud, blood – there are many agents that can make gripping your knife a challenge. Since I wanted to start tests in a reproducible manner, I used lubrication gel to simulate all of the above. The result was a handle that was way more slippery than what you might ever have in a real life situation. The lube not only made the handle extremely slippery it also filled the milling on the handle.

As a result, chopping was only safe with the lanyard on. I could get a firm grip but still the excessive force caused the handle to move a bit in my hand. Still, I hacked the knife into the edge of a very heavy piece of a cut down tree. I could lift the piece with just the knife as a handle. Well, only a centimeter or two but that was mostly because the piece was too heavy for me to just lift with one hand.

Of course you need the fingers notch in the handle for a real tight grip. When it’s slippery like that, only using the end is not a safe option anymore. If you take the lanyard then you can work just fine. But that’s more a test of the overall design, not just the handle.

Stain on the blade

Not a real test but a thing I learned while running the M200HT through the paces. The Sleipner steel needs some coating because it’s not “stainless”. If you know a bit about knives and steel then you know that great steel usually catches stain fairly easily. The more it’s “stainless” the worse are a steels specs when used for a knife. (Of course, there are exceptions like always).

So after one of the last tests I didn’t take the time to clean the blade properly before putting it back in it’s sheath. Stupid me even forgot to clean it later. So on the very edge I found some spots of stain – which is absolutely fine. These are just on the surface and will disappear after use or the next sharpening. I also found some spots on the DLC coating: little circles with a dot inside. That’s usually how rust on a blade looks so I was a bit alarmed. But after a short rubbing with some Ballistol oil they were completely gone. So again, nothing to complain about, everything like it should be.

Starting a fire with the M200HT

One of the most basic tasks in bushcrafting and survivalism, starting a fire is always a good test to see what a knife is worth. To make it a bit harder I decided to use only the M200HT and a firesteel and wood I found on site (not on the way). I chose a place on a riverbank. Lots of flotsam and jetsam and no danger of starting a wildfire. One thing to keep in mind is that wood that was in a river for a long time lost a big amount of it’s burn value. It’s harder to start and harder to keep up.

I grabbed a few sticks that looked promising and got to work. The M200HT could make it all. I used batoning to split bigger pieces and then made fine sticks to get it going as well as very fine shavings to catch a spark. This way I could test how the knife would handle the fine shaving after hammering it through wood (and eventually hitting the rocks).

The outcome of making a fire with the M200HT

My conslusion: The M200HT can handle hard and fine tasks just great. And it doesn’t matter in which order you do them.

Using the notch for the fire steel is a bit tricky, though. You need to get used to the angle that makes the best sparks. I also tried using the edge of the blade (which you shouldn’t) and both ways did work. The only drawback were a few stains from the ferrocerium on the DLC coating. They were quite a pest to remove. Finally I succeeded by scrubbing the blade with a cleaner for glass ceramic cooking surfaces. The DLC looks like new and not even the markings show a scratch.

After all this, again, the knife was still sharp enough to shave some hair off my body. But you could tell that it didn’t make the hair “jump” like before. Razor sharpness, as I said in another post is mostly to show off. More important is that the knife keeps a decent sharpness to handle real world tasks.

My conclusion about the ANV M200HT

Well, just as I expected after I had the knife in my hand for the first time. For a very, very long time, I only had one personal favorite when it came to knives. Now suddenly I have three. And the Acta Non Verba M200HT is one of them. Knives are a very important part of my life since I was a kid so I’m not easily impressed. But this beast really did it. I threw a lot at it but so far it handled everything like a breeze.

The difference between the three is that the M200HT is not only a really “cool” knife and not extremely overbuilt. It’s also a very sensible tool that you can suggest to people who only need a tool and aren’t into knives at all. People who frown upon huge “killerblades” might still accommodate to this fine knife.

The M200HT is a mighty blade and it will withstand whatever you use it for. At the same time it’s reasonably built and I mean that in the most positive way. Many outdoor knives are overbuilt and focus only on being virtually indestructible. While I like that approach personally it’s not very sensible when you really have to rely on a tool. The M200HT on the other side is maxed out in balance between toughness and usefulness. I doubt that you will be able to break it as long as you don’t try it on purpose. But still it will handle tasks in the field or a survival situation just perfectly.

Closing words

One more general thing about Acta Non Verba is still to say. I read Pinesurveys review again to see where we agree and where, if, we disagree. (See link above). And then I realized that the M200HT has evolved lately. In his review he says, his has a N690 blade while mine is of Sleipner steel. And the sheath is similar but definitely different. So ANV is still evolving it’s knives which is just great!

I will keep working with this knife and if I find something new, I will update this post.